Categories

- Guitar Playing (4)

- Ham Radio (4)

- Model Flying (18)

Archives

- April 2024 (1)

- July 2022 (1)

- August 2021 (1)

- May 2021 (2)

- August 2020 (7)

- June 2020 (1)

- May 2020 (1)

- October 2019 (1)

- November 2017 (3)

- June 2017 (8)

Toothpick

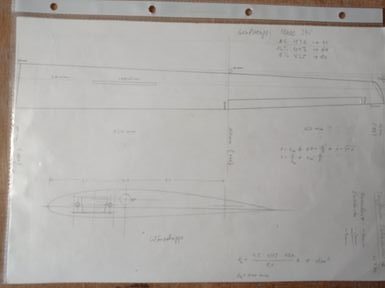

This is the story of how I designed and built the second version of my glider “Toothpick”.

I flew the original version at competitions in 1988 and 1989. The special thing about this model was the very high aspect ratio of the wings.

I already published some data about this model in a previous post. (Contest Flying)

I was very satisfied with the flight performance at the time. Unfortunately, in 1990, I had a collision with a model of my friend Frank Neumann while flying slopes. My “Toothpick” was completely destroyed.

Very soon I made plans for a successor.

I built a new pair of wings out of Styrofoam and Abachi veneer.

Luckily Christoph Sarter still had the negative mold for the fuselage, so we were able to laminate a new one together.

Since I was very stressed by my job as a teacher in 1990, I had to interrupt my work on this model, and provisionally stored the half-finished parts.

In 1994 I joined a group of model pilots who flew F3B competitions. We started working together to make negative molds for our own F3B model. I forgot about my “Toothpick” project because I thought it was no longer competitive anyhow.

After we held a meeting of senior RC-4 competition pilots in 2022, (I reported about it in my “Phoebus” post), I remembered the old parts of my “Toothpick”. They were still lying around in my basement and had survived my two moves to new apartments in relatively good condition. Now I thought it was time to finish the construction.

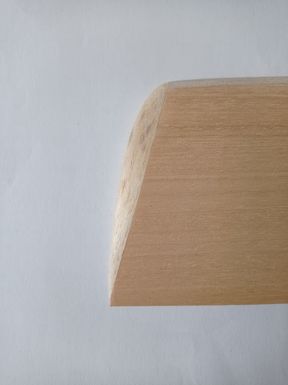

The leading edges of the wings were sanded to shape and the wing tips were finished.

Root ribs were prepared and glued to the fuselage.

The gaps were filled and smoothed.

The support for the horizontal stabilizer was adapted to the vertical stab.

Before…

And after…

Rudder and horizontal stab were made.

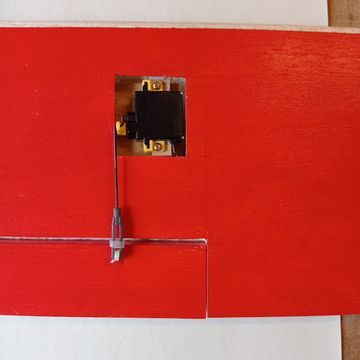

The ailerons were cut out and adjusted. The corresponding servos and push rods were installed.

The servos for rudder and elevator, the receiver and the battery were installed.

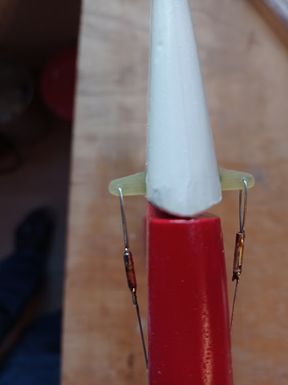

The rudder is operated with litz wire, which dates back to when I was building control line models.

The hatch cover is fastened with a magnet.

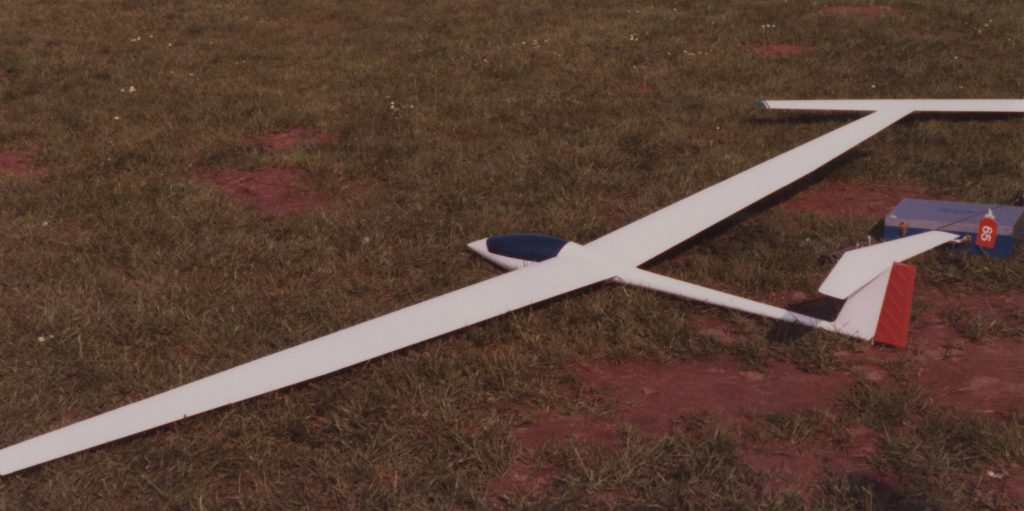

Here you see the finished product.

The maiden flight was on April 6, 2024. It flies! But I realized that the center of gravity needed to be moved further forward.

The Phoebus Project

There was a special reason to start this project. I had not flown any contests since 2001. On October 7th 2021 Marc Schneider initiated a WhatsApp group called “RC4-E” and invited pilots to this group who had flown this class in the 80s and 90s of the last century. The idea was to organize a meeting and to fly a contest to the original rules just for fun. More and more participants in the competitions of that time found out about this group and became part of it. In the end the group had 12 members. Everyone was very enthusiastic about this idea and proudly showed their models that they wanted to participate with.

Now my problem became obvious: All my models that I had used in those contests were either damaged or in very bad shape. The only solution was: I had to build something new. The scheduled time for the meeting was late May 2022, so I should have plenty of time to build a new model.

I first went down to my workshop in the cellar to find out what material was still there. Balsa wood and plywood in various thicknesses and pine strips were available in sufficient quantities.

Then I found the pod and boom for a fuselage which were given to me by Enrico Vettermann in 1990. They were still waiting for a good use.

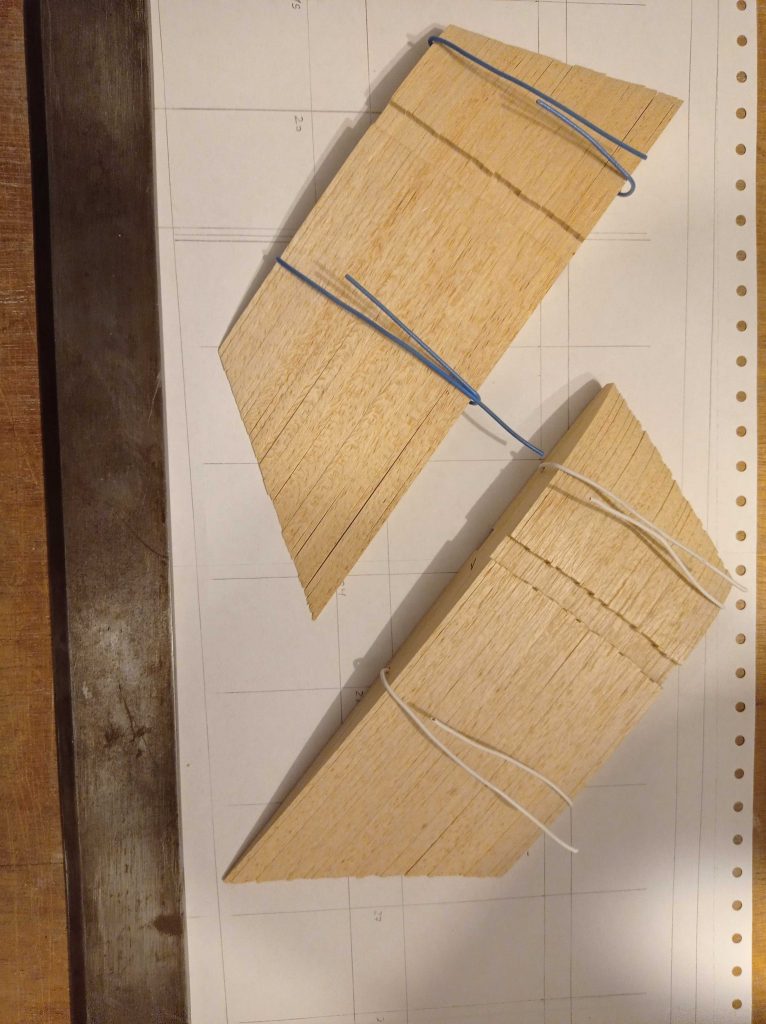

In the same year I had produced a pair of rib blocks for my father as a gift for his 69th birthday. Sadly, my father died in January 1991 and could not make use of them any more. The ribs were still laying around in my workshop in a plastic bag in perfect condition. I decided to use them now for my new model.

The airfoil was a Clark-Y with reduced thickness of 10 percent.

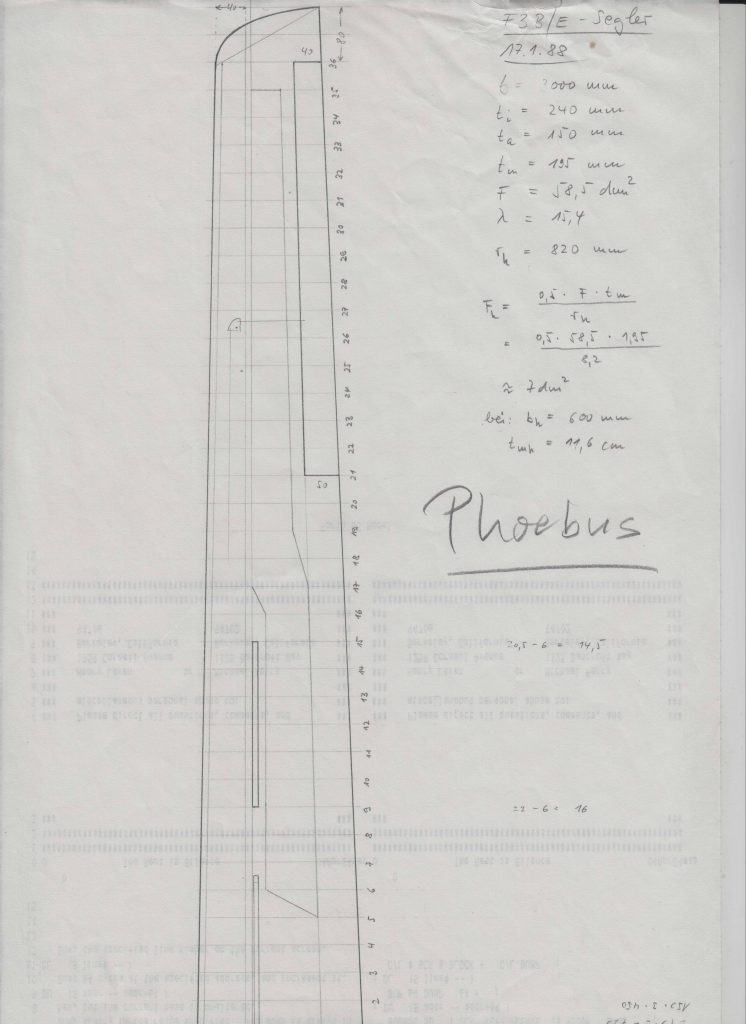

In January 1988 I had already made a rough scaled down drawing of a wing that should be suitable for my new design. The intended span should be about 3000mm (~118″), the root chord 240mm (~9.5″) and the tip chord 150mm (~6″). That should result in a wing area of about 58.5 dm2 (~907 in2) and an aspect ratio of 15.4. The wing should only be partly planked to save weight. At the end I wanted to reach a total weight of the model of well under 2kg.

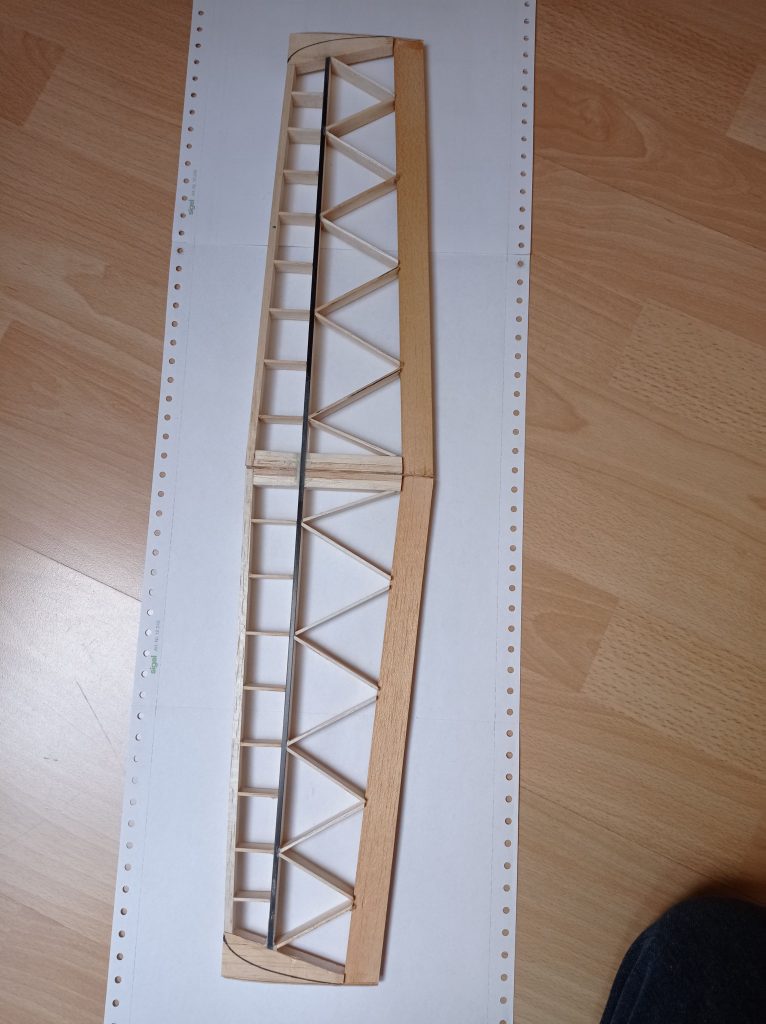

I made a drawing of the right wing in original size. Fortunately, I had a lot of old endless printing paper that was very suitable for this. To start building, I glued together the lower skin of the wing (balsa 1.5mm; ~1/16″).

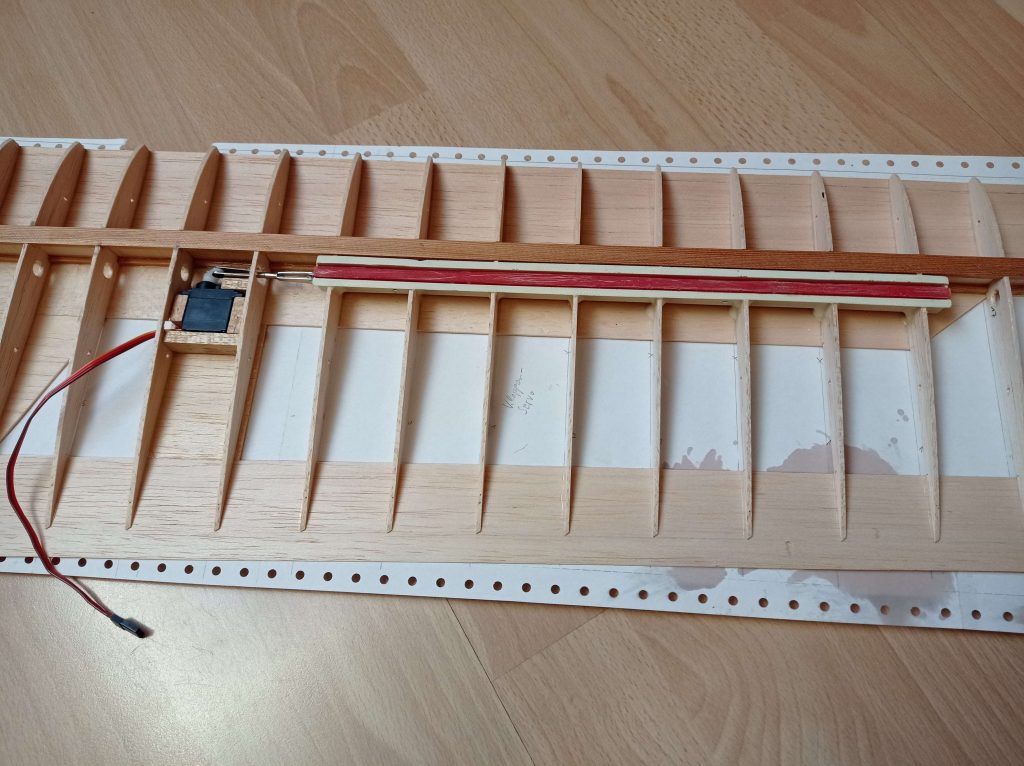

After that I glued on the lower spar (pine 10mm x 3mm; ~8/20″ x 1/8″) and the ribs (balsa 2mm; ~1/12″).

After gluing in the webs between the ribs (balsa 3mm; ~1/8″; vertical grain)…

…the upper spar could be added.

In a hidden box in the farthest corner of my workshop I found a pair of spoilers that I had salvaged from an older crashed model. They fitted nicely into my new wings.

The spoiler servo was permanently glued to the bottom skin between two of the ribs. I used Corona DS939HV servos in all locations.

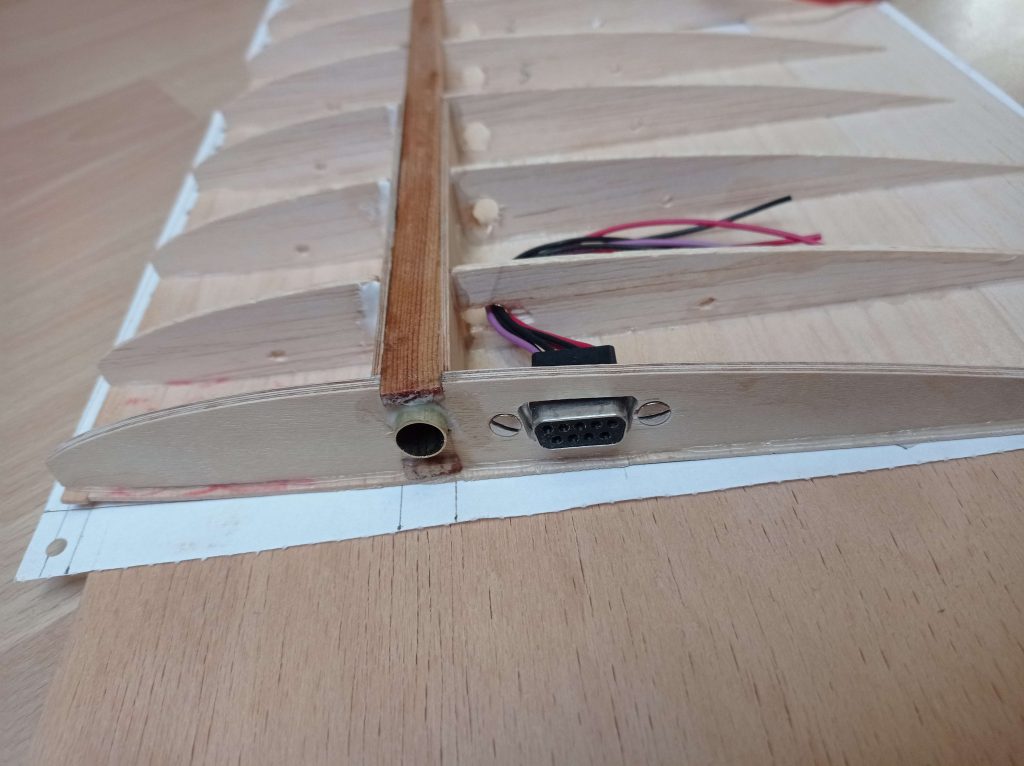

The webbing between the first four ribs was made of plywood to withstand the strong forces in this area. The wings should be attached to the fuselage with a round steel rod (8mm diameter; ~1/3″). For this I glued brass tubes between the spars at an angle of 3.5 degrees to get the right dihedral for the wings. The cavities were filled with epoxy. A Sub-D socket was attached to the first rib for the electrical connections to the servos.

After completing the wiring, the top planking and the rib caps could be glued on.

The leading edge and wing tip block were attached and the ailerons were cut out.

As I did not have enough space in my workshop to build both wings simultaneously, the left wing was made afterwards.

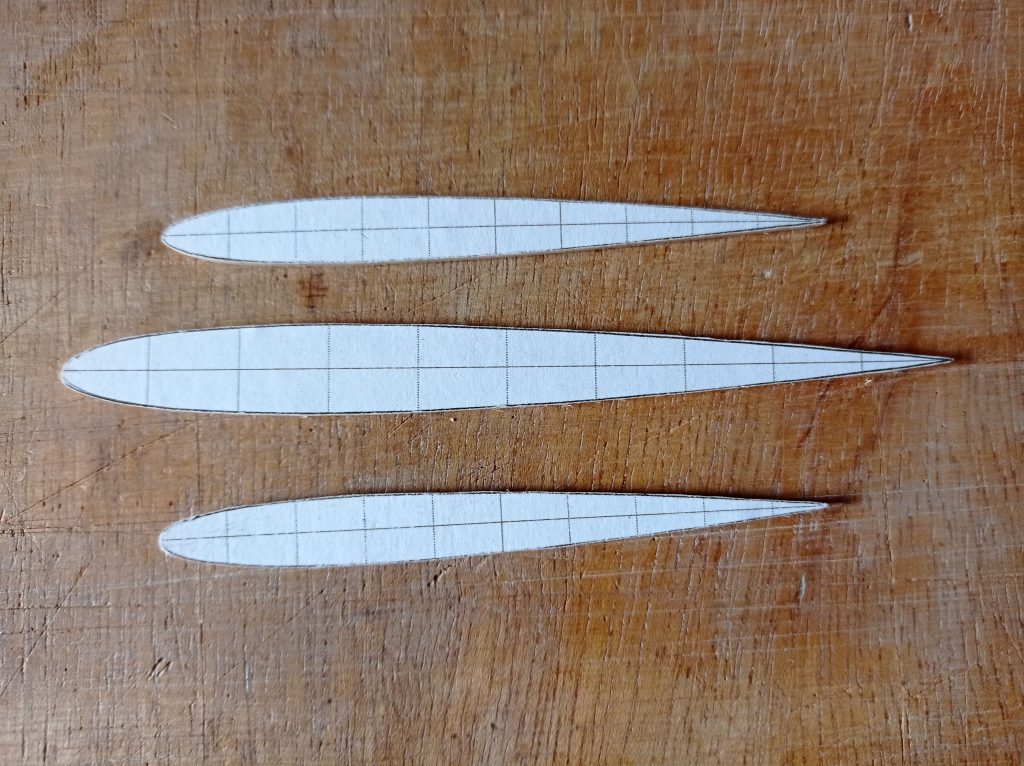

Now I made a drawing for the horizontal stabilizer of the t-tail. Depending on the length of the fuselage (distance between the wing and the stab), I calculated the area of the stab at 7 dm2 (108 in2). A grid of square ribs and a spar were glued together. The narrow spacing of the ribs in the front should prevent sagging in of the skin and the zig-zag arrangement of the ribs in the back should prevent twisting of the stab. The spar was reinforced by a carbon fiber rod.

Symmetrical airfoil ribs made of plywood (NACA 0010) were attached and the complete structure was sanded to the right shape.

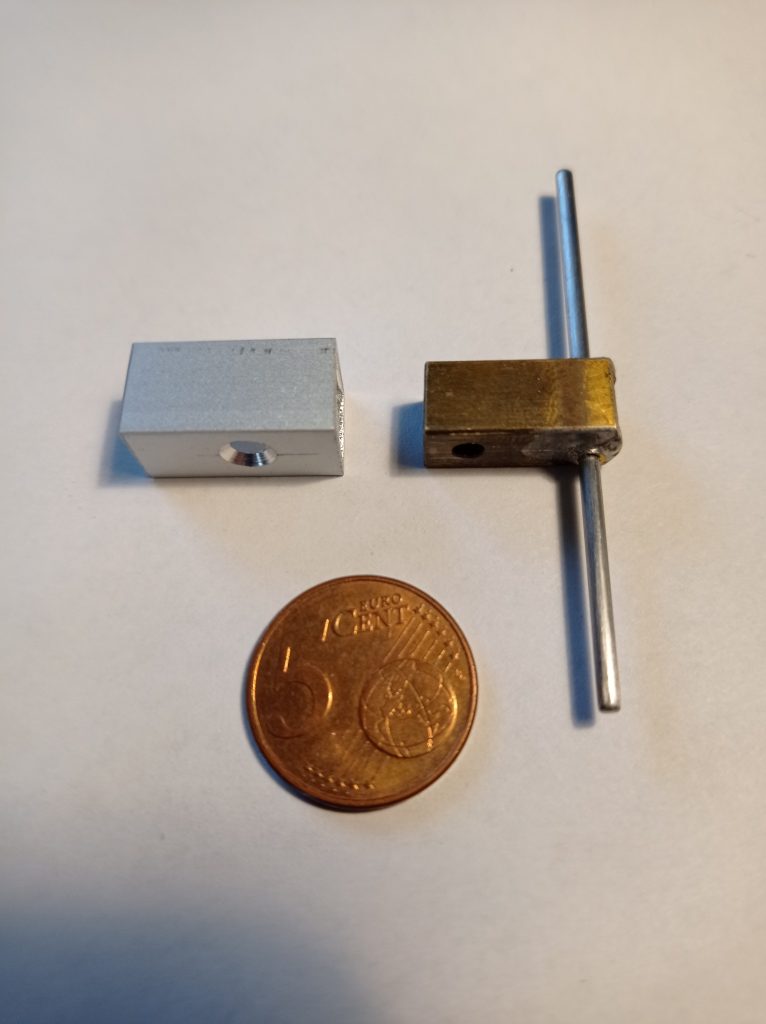

Into the underside of the tailplane I glued kind of a hinge consisting of a short piece of brass tube and a steel pin.

The short aluminum tube was later glued into the top of the vertical stabilizer, where the brass tube is fastened with a small 3mm (M3) screw.

First I wanted to laminate the vertical stabilizer with fiberglass into a mold that I had received from Horst Baum many years ago.

Unfortunately, because of my lack of experience and because I didn’t have a good vacuum pump, this wasn’t successful.

So I decided, to build the vertical stabilizer in rib and plank construction from balsa wood. The skin (balsa 1mm; ~1/24″) was reinforced inside and outside with very light glass cloth. The servo for the horizontal stab was permanently glued inside. The next picture shows the completed vertical stab, including the rudder, glued to the fishing rod boom of the fuselage. The thin wire hook extruding from the top is the end of the push rod coming from the servo.

The rudder is operated via two thin control line wires by the only one servo needed inside the fuselage pod.

Approximately 200g (7 oz) of lead shot had to be glued firmly into the nose of the fuselage to achieve the correct center of gravity.

The next picture shows the finished model in my garden.

It came out at a total weight of 1600g (56.5 oz).

I finished the model only five days before the planned meeting at the Hesselberg. Therefor I did not have the chance to fly it in at home. This would have to be done directly on the mountain.

When my wife and I arrived there, I was overjoyed to meet and greet seven other pilots and their wives. Unfortunately the weather was bad and the strong wind was coming from the wrong direction. Therefor slope soaring was not possible. I did not want to risk my model in such miserable conditions anyhow.

We decided to meet meet again the next day at the local model flying club’s airfield at the foot of the mountain, hoping for better conditions. We didn’t really have a competition, we decided to just have fun and fly as much as possible. With foresight, I had packed my high start towline at home. Joachim Regel also brought one and Christoph Sarter installed his F3B winch.

The next picture shows our group on the Grueb airfield presenting our models:

The pilots in the back from left to right are: Me, Stephan Laemmlein, Enrico Vettermann, Frank Neumann, Gerhard Schmidt and Christoph Sarter. Kneeling in the front are Marc Schneider and Joachim Regel. The Hesselberg is visible in the background.

Now my model was flown in successfully and I’m very happy with the result.

In the meantime I have tested the model a lot on the local flying field of the Sportfliegerclub Darmstadt near Messel. The original CG had not to be changed. During the high start the model climbs steeply without any risk of breaking out. When circling in the thermals I realized that a lot of rudder control is needed. The dihedral of the wings is quite high (3.5 degrees per side). So, very little aileron control is necessary. The model seems to dive into the circle easily and needs a lot of up elevator. But that could just be a matter of getting used to it. Maybe, the horizontal stabilizer could be a little bigger. I made some rolls, both against the wind and with tailwind. That worked out well, but the rolling rate was quite slow. So, it is definitely no aerobatic model, and that was not my intention.

Local Club Activity

From the seventies to the early eighties I was a member of the Elmshorner Modellbau Club.

Almost every year a gliding contest was held with many participants who were all members of the club:

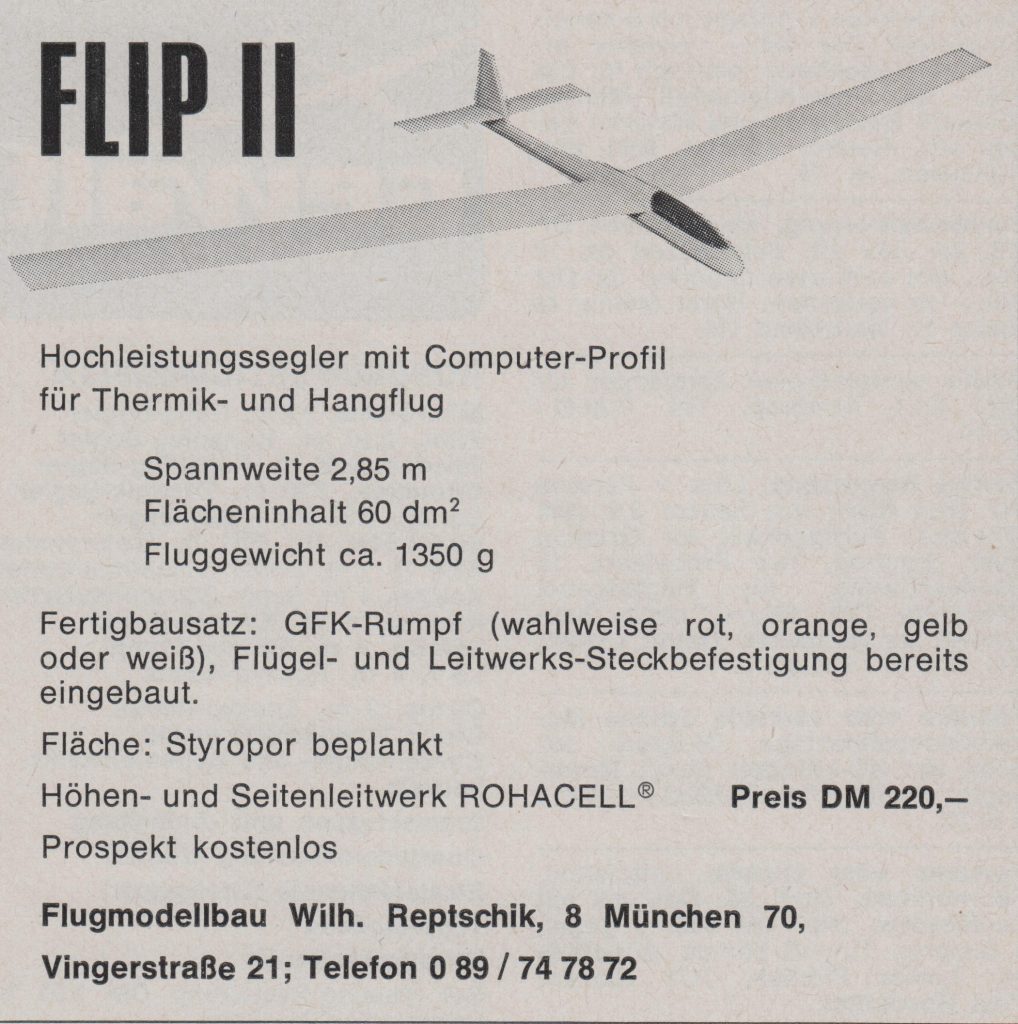

You see me kneeling in the foreground on the left. My model is a FLIP II that I built from a kit. Here is the manufacturer’s ad from 1973:

My father is holding the model with the largest wingspan. He always loved big models.

I’ve won the trophy for several years:

The next picture shows me in a deck chair during a one hour flight with my FLIP II:

My father is preparing his DRANA sailplane. This was a design of Erich Dreessen from Neumuenster. We bought several fiberglass fuselages from him and added our own wings. Erich also sold very high quality balsa wood.

The next picture shows me in 1981 with a model that I built using a SPRINT fuselage by Erich Dreessen:

I built the wings with a span of 3.2 meters and a root chord of 27 centimeters. The performance was excellent. I lost the model in Frankfurt when I started it with a broken receiver antenna and lost control.

Here you see another picture of my SPRINT laying in the preparation area of the Elmshorn flying field:

My father is holding the wings of his latest DRANA.

Contest Flying

In 1977 I went to Darmstadt to start my studies of electricity and mathematics at the “Technische Hochschule“. Soon I became a member of the “Sportfliegerclub Darmstadt“. Those pilots were very active in contest flying. The most flown class was F3B/E for model gliders. The task was to fly for exactly 200 seconds after a high start with a fishing line of 100 meters length (hand towing, no winches, no rubber). You had to land in the center of a circle of 15 meters diameter. The elegance of the landing approach was also rated. This means that the model had to fly straight for at least 10 seconds, sink evenly and touch down gently without bumping or turning. This was practically only possible if the model had ailerons and spoilers.

The next picture shows me as a participant of a Hessian F3B/E contest in 1989 in Braunfels, bringing my model back to the preparation area after landing:

From my head-down posture, you can imagine that the flight wasn’t too successful (grin).

Here is another view of my model:

The man with the number 11 is Horst Baum, who assisted me on this flight. He is an excellent pilot and model builder (better than me).

P.S.: Regrettably, Horst Baum died on February 4, 2024. RIP

The model is my own design with a fiberglass fuselage made by Christoph Sarter. It has 3.2 meters wingspan and weights 1.8 kg. The wings have a high aspect ratio, with a root chord of 180mm and a tip chord of 90mm. The root airfoil is a semi symmetrical RITZ 2-30-12 (for mechanical strength) and the airfoil of the outer third of the wing is a CLARK-Y, thinned down to 10 percent . This sounds a little strange for a thermal flyer. But the performance is very good, especially in windy conditions. I cut the cores for the foam wings in the workshop of Hermann Fading.

Slope Flying

In the late seventies and the early eighties my father and I were very active in slope flying. So far we only knew the Wasserkuppe in the Rhön as an important slope flying area. And only from the stories of other model pilots, because we had never been there before. Then we accidentally discovered the Hesselberg in Franken (Northern Bavaria). We found accommodation in the Rötter brewery close to the mountain in Gerolfingen. We spent our summer holidays there for several years. The picture shows me standing on top of the mountain flying one of my models:

Almost every year another model pilot spent his vacation time there, who became very important for the development of my hobby. His name is Hermann Fading. His models (always his own designs) are superbly built and he is a master at locating thermals. From him I really learned thermal flying. In the following years I spent many days in his workshop, where he showed me how to build wings from Styrofoam, glass fiber and Abachi veneer.

The next picture shows my SB-11 with 4.5 meters wingspan which was designed by Hermann:

I built the wings in his workshop because at that time I had no way of building models in my small student dorm.

My Model Flying History (1965)

1965: This year was very important for me. I designed and constructed two glider models. The first was quite a failure. It was built way too heavy and the wing had a constant chord, which was unfavorable. It didn’t fly very well and broke after only a few test flights. Unfortunately I don’t have any photos of this model. I received a lot of information from the experienced model pilots from Kaltenkirchen about the mistakes I had made with this model. Therefore, the next construction should be much better.

In the meantime, my friend Joachim Jürgensen had designed and built his own model. The special thing about it was that the wings were very much tapered. The root chord was 200mm and the chord of the tip was only 100mm. This model had a very good glide angle as long as it was flying straight ahead. As soon as you tried to make a turn, the inner wing tip stalled and the model began to spin. It was almost impossible to fly.

So it was clear to me that I had to find a better compromise here. My new wings got a root chord of 200mm and a tip chord of 150mm. In addition, over the last third of the half span the wing got a washout of about 2 degrees, in order to prevent the tip stall.

The picture shows me, holding the model. I published more information and more photos in another post.

My father had built another sailplane of his own design:

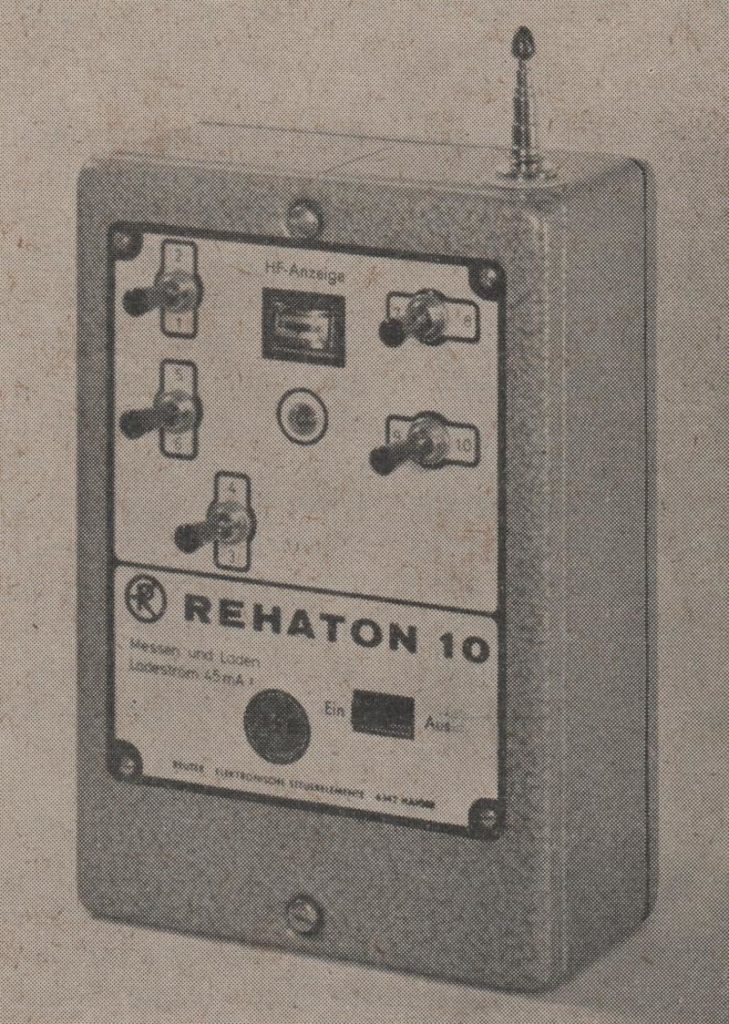

It was a bigger than mine (2500mm wingspan) and already had rudder and elevator control. We had built a new radio from kits offered by the “Reuter” company.

The picture shows the fully equipped 10-channel version of the transmitter. Ours only had 4 channels (two sticks).

My Model Flying History (1964)

1964: I don’t have many memories of that year. I also couldn’t find any photographs. I started playing guitar in 1962. More about that is in another post. So I guess I spent most of my time on it. I also did something with electronics. It was mainly about circuits for remote control, but also about detector-receivers for radio reception. We certainly went to Kaltenkirchen a lot to fly our glider models there.

My Model Flying History (1963)

1963: In the meantime, our interest in a powered radio-controlled model grew again. In the “Modell” magazine we saw the picture of the “Tele-Pilot”. It was a design of Heinz Siegle and offered by the “Engel-Modellbau” company (it no longer exists today). At the Vietzke model shop we found the “Engel”-catalog and we ordered the kit. Here is the page of a later catalog. The price was not too high. It was a bigger model with a 65 inch wingspan and a large dihedral. We were convinced that this model had to fly well. In our opinion this big plane needed a big engine. So, an OS-Max 29 with 5cc displacement was ordered.

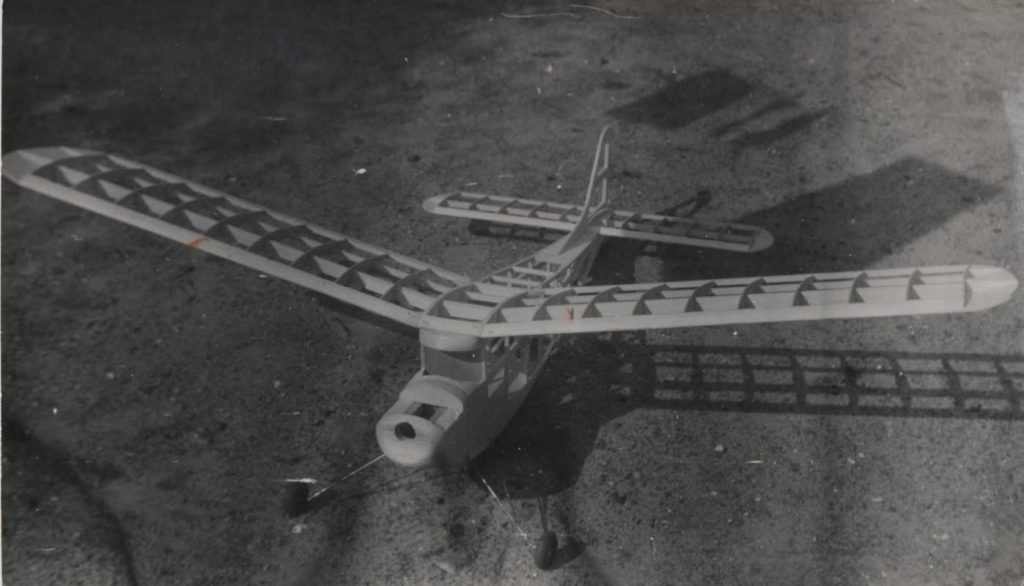

Since our garage was now occupied by our car, it could no longer be used as our workshop. Fortunately we were able to free a corner in our cellar room and install a workbench there. When the kit arrived, we started the assembly in our new cellar workshop. It went together without any problems. The following picture shows the completed uncovered frame without radio and engine installed:

The next picture shows me presenting the frame in front of our chicken house:

The frame presented by me (wearing the famous Lederhosen) in the backyard of our house:

It was an impressive model for sure.

A few weeks later we proudly carried the model to our local grassland “airfield”. Of course there were some curious spectators again. We made some initial hand starts without the engine running. The model glided smoothly like a sailplane. The center of gravity and the longitudinal dihedral angle were obviously correct. We dared to try the first powered flight. The engine was started without any problems. We tested the radio (Metz-Mecatron) and it worked flawlessly. The engine could be throttled by the third channel of our radio. Push the button: engine idling. Push the button again: full speed. The next picture shows the model just prior to the first flight. I hold the transmitter, my father gives commands and the son of our neighbors, Holger Tamm, assists us.

I took over the transmitter, my father threw the model in the air. It went up straight, beautifully and evenly. It responded to the rudder instantly and so I let it make a big left turn. In very short time the model reached a height of about 100 meters. What a beautiful sight. When I thought that it was high enough I pushed the button for low engine throttle. That worked well and the engine slowed down. But even in this throttled down position, it still had so much power that our model continued to climb. Obviously we had too much engine power. Our OS-Max 15 would probably have been sufficient. But how should I get the model down now? We couldn’t let the model climb until it was finally out of sight.

The tank was still rather full and we had no elevator control. I got the idea that a spiral dive would be the right method to get the model down. So I gave full left rudder. The spiral began and the model quickly lost height. I put the rudder back on neutral to end the spiral but the model didn’t want to recover. It did not even react on full right rudder. The spiral continued. Eventually the model disappeared behind a house and could not be seen any more. We didn’t hear the crash but it was clear: the model hit the ground somewhere. Great horror! We quickly ran in the direction where we suspected the impact would be. Behind a couple of houses we eventually found the debris in a ditch between a front yard and the street.

In our opinion this was beyond any repair. With the experience I have today I would have repaired it. Despite the total loss, we were still rather lucky. The model could have hit the roof of a house or injured or killed a person.

In retrospect, it was also clear to me that our “airfield” in Elmshorn would have been too small anyway for an orderly landing approach. We decided to make our next attempts only in Kaltenkirchen.

My Model Flying History (1962)

1962: My father had finally made a driver’s license for a car. Our first car was a used Volkswagen Van that was missing the middle bench. Now we could drive to the Kaltenkirchen Moorkaten airfield more often on weekends. This airfield originally was a military training area. But the local club FAG (Flugtechnische Arbeitsgemeinschaft Kaltenkirchen) was allowed to use it over the weekends. There we could see for the first time how radio-controlled models were properly flown. In addition to some powered models of the RC1 class (today F3A), there were mainly sailplanes of the RC4 class (today F3B). The models were started up with a 200m long nylon cord by a runner using a pulley. A rubber high-start was not common at that time because it was not allowed for competitions. And the members of that club were very active competition flyers.

In a kiosk in Elmshorn I discovered the “Mechanikus” magazine. It not only contained very interesting articles on the design and construction of model aircraft but also on model ships and model railways. From now on I bought and read every issue of this monthly magazine. Werner Thies, in particular, has to be mentioned here as an author who described his glider models in detail. And he also was the chairman of FAG Kaltenkirchen. I learned a lot from him.

Very soon our decision was made: our radio control units had to be installed into a glider. Of course we didn’t want to buy a kit. We were brave enough to design it ourselves. It had to be a little bigger than the “Geier” because of the weight of the radio control. The fuselage should look elegant, so a simple box construction was not an option. Since we couldn’t afford a fiberglass fuselage, we built an oval one from balsa wood. The wings got a span of 2.50 meters (nearly 100″) and were fastened with tongues and boxes, as we knew it from the “Geier”. The sizes of the horizontal and vertical stabilizers were calculated according to the instructions by Werner Thies. Our radio only allowed rudder control. We didn’t think about spoilers yet.

Some weeks later we went to Kaltenkirchen with the finished model. A few other modelers were already there and eyed up our plane when we took it out of the car and assembled it. At first we tried some hand launches. Helmut Noffz, one of the experienced model pilots, watched us with interest and finally said: “The balance point is not correct!” He balanced the model with his fingers under the wings and found that the center of gravity was to far back. We had determined it according to our experience with the free-flight models “Donald Duck” and “Geier” and that was not right for a radio controlled glider. Mr. Noffz showed us where the balance point should be and that was in the first third of the wing chord. He had a few pieces of lead in his toolbox. We cut a slot in the model’s nose block with a knife and temporarily stuck the lead pieces inside. Now the hand launches looked a lot better and the model glided beautifully. Eventually, also the position of the tow hook had to be corrected. After that, we dared to make a first high start, which went without any problems. The model climbed straight up and was released at a height of more than 100 meters. It was very easily controlled and flew more than two minutes. The landing was not very close to us, but the model remained intact. What a sense of achievement! We drove home thoroughly happy.

I had been interested in control line flying the whole time. So we looked for a model kit that should be appropriate for the Hurrican engine. We decided on the “Ultra-Stunter” from Graupner. My dad assembled it because the fuselage had an oval cross section and therefore was a little difficult for me to build. Of course we had to buy a lot of additional accessories again. The most important one was a tethered flight grip “Meister” from Graupner which already included the wires. The finished model should be tried out on our small grassfield near our home. We were watched by a number of curious onlookers. The lines were laid out and the engine started. I should do the first flight. My father released the model. It immediately took off and went into a loop. I was so surprised that I couldn’t react fast enough. Before I could give down elevator, the model was already descending. The loop merged into a figure nine, which ended with full speed in the ground. Everything was totally destroyed and hardly repairable. We were utterly ashamed and disappointed. The Ultra-Stunter was an aerobatic model with extremely effective control surfaces. It was therefore completely unsuitable for beginners. We should have studied the description in the Graupner catalog more carefully.

A few months later I built a new control line model together with my friend Joachim Jürgensen. When designing it, we made sure that it was easy to fly for a beginner. I found instructions for this in the book “Fesselflug-Fibel” written by Gernot Nobiling. If only I had read this book beforehand! This new model flew without any problems and was easy to control. We had a lot of fun with it.

My Model Flying History (1961)

1961: So far I had assembled my models on the kitchen table. In the meantime we had cleared our corrugated iron garage so that we could use it as a workshop. We didn’t have a car back then. The next project was the free flight model “Donald Duck” of class A1 from Graupner. Unfortunately, we had made a mistake during construction: The trailing edge strip of the wing was not raised at the front but laid flat on the building board (as we knew it from the “Little UHU”). Therefore, the airfoil was incorrect and the flight performance was correspondingly poor. The model already had curve control and a thermal brake. We coped well with that and made a lot of flights. A fuse was used to trigger the thermal brake.

Next, a larger free-flight model was needed. It was a “Geier” of class A2 (now F1A) published by the Robbe company. It promised to be a competitive contest model. There was no kit available, just a blueprint. So we built everything completely from raw material. The model had a two piece wing and we got to know a tongue and box attachment. This time the airfoil was built correctly and the flight performance was impressive. We gained a lot of experience with this model.

One day, while browsing the Vietzke model shop, I discovered the book “Funkfernsteuerung fuer den Modellbauer”. It was a translation by H. Bruss and Hans-A. Pfeil of the English title “Simple Radio-Control” by H. G. Hundleby. I absolutely had to read that. I literally soaked up the content and that was my first contact with radio technology. I still have this book and I still like to look inside. It’s very tattered now.

From time to time we went to Hamburg, the next big city, for shopping. On one of these occasions we also visited the large model making department of “Spielzeug Rasch”. That was of course not to be compared with the small shop in Elmshorn. Our eyes widened more and more when we saw the many model kits and radio control sets that were on display. However, everything was so expensive that we couldn’t afford it. After all, we bought a few copies of the “Modell” magazine that we found there. I read all of them from cover to cover and was thrilled by all the new information. I was able to persuade my parents to subscribe to this magazine.

At the end of the summer we visited a model air show at the Hartenholm airfield near Bad Segeberg. What impressed me most was a biplane called “Captain”, which was flown by radio control. The model performed wild capers in the sky and hardly ever flew straight. It only had a 1-channel system with a rubber powered escapement. Today I know that the pilot probably had problems calming the model down with the right commands. Only when the engine finally stopped the flight became straight and the landing succeeded rather smoothly.

Some model shops exhibited their products along the site. One of them was the Carl Leonhardt company from Bad Segeberg. I was particularly interested in the new 3-channel radio control system produced by Metz. It seemed to be comparable to the Graupner “Bellaphon” system that we knew from the magazines, but was much cheaper. We took some handouts and leaflets with us, to study them thoroughly at home. I still have them.

My father had worked overtime and saved some money. We therefore decided to order the Metz 3-channel system at the Vietzke model shop. After a few weeks it actually arrived and we were able to pick it up. Of course, it had to be officially registered with the Federal Post Office and a fee of 10 DM had to be payed every year. I still have the certificate.

Now of course we needed a new model for it. Although it would have been more sensible to build another glider, it now had to be a model with an internal combustion engine. The “Satellite” model was particularly recommended for this purpose in the Graupner catalog. This was a replica of the American model “Live Wire” by Harold De Bolt. But the kit was very expensive. You could get the new “Piper Tri Pacer” for much less money, and it looked even nicer. So we decided on this model. We later realized that this was a mistake.

My father built the model almost alone because it was to complicated for me. Of course, only the “Taifun Hurrican” Diesel engine was considered as the drive. It had to be broken in first. Back then, you could run an engine in the garden without a silencer without being scolded by your neighbors. During the working days, my father took the compression lever with him so that his son would not be able to run the engine while he was away. He knew me!

Eventually, the “Piper” was ready to go and we made our first attempts on the grassfield near Wittenberger Strasse. However, we found that the “Piper” did not want to roll properly in the tall grass to gain enough speed for takeoff. We had, of course, attached the beautiful wheel pants. So we found a tarmaced field path nearby for our next trials. But the model always only rolled a few meters, broke out to the side and stuck in the high grass aside of the road. It didn’t want to take off.

We came to the conclusion that the engine was to weak. So we needed a bigger one. This time it should be a glow plug engine. The OS-MAX 15. Of course, new accessories were needed. A glow plug clamp, a starter battery and a different fuel. After breaking in, the engine was installed in the “Piper”. But the following attempts to start were just as unsuccessful as before. The model didn’t want to take off. We could have tried to start the model directly from our hands but didn’t dare to do this.

Out of desperation, we contacted my father’s colleague Gerd Mix again and met him in Kollmar at the Elbe. He was a very experienced model pilot and took a close look at our “Piper”. He found no serious flaws and thought the model should definitely fly. We should try to start it directly from our hands . Together we went to the beach and started the engine. Gerd Mix took the model and threw it firmly into the wind. The model stalled immediately, turned on her back and crashed into the ground. Almost everything was broken and looked beyond repair. We never found the reason for this failure. For us this was the end of the “Piper” experiment.